Retos del Sector Alimentación

La industria alimentaria se enfrenta a numerosos desafíos que la automatización puede ayudar a resolver:

- Garantizar la seguridad alimentaria y cumplir con normativas cada vez más estrictas

- Mantener la calidad y consistencia de los productos

- Optimizar procesos para reducir desperdicios y aumentar la eficiencia

- Adaptarse a cambios en la demanda y preferencias de los consumidores

- Gestionar la trazabilidad de los productos a lo largo de toda la cadena

- Reducir costes operativos manteniendo altos estándares de calidad

- Minimizar el impacto ambiental de los procesos productivos

Soluciones de Automatización para la Industria Alimentaria

Robots para Manipulación de Alimentos

Robots diseñados específicamente para la manipulación de alimentos, con características como resistencia a la humedad, facilidad de limpieza y cumplimiento de normativas sanitarias.

Aplicaciones: clasificación, pick and place, corte, procesamiento, envasado.

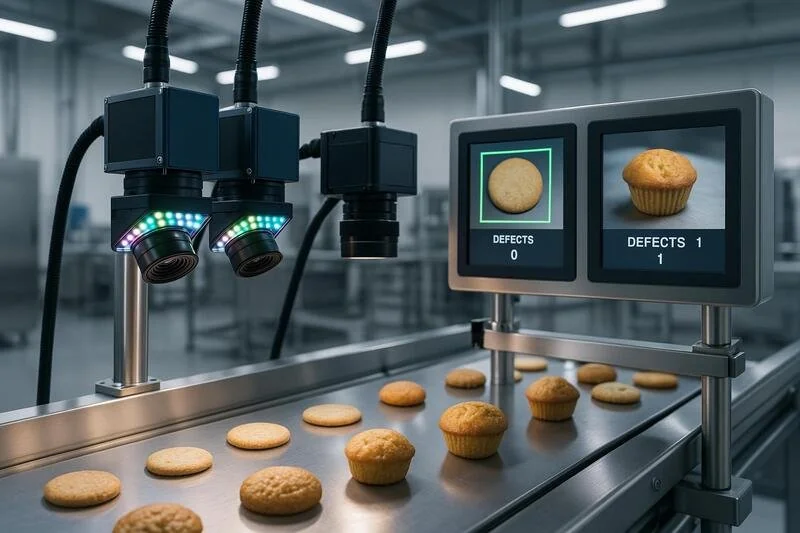

Sistemas de Inspección y Control de Calidad

Tecnologías de visión artificial y sensores avanzados para detectar defectos, verificar etiquetado, controlar pesos y garantizar la calidad de los productos.

Aplicaciones: detección de cuerpos extraños, verificación de sellado, control de llenado, inspección de etiquetas.

Sistemas de Envasado Automatizado

Soluciones completas para el envasado de productos alimenticios, desde el llenado hasta el paletizado, garantizando eficiencia, precisión y seguridad.

Aplicaciones: llenado, sellado, etiquetado, encajado, paletizado.

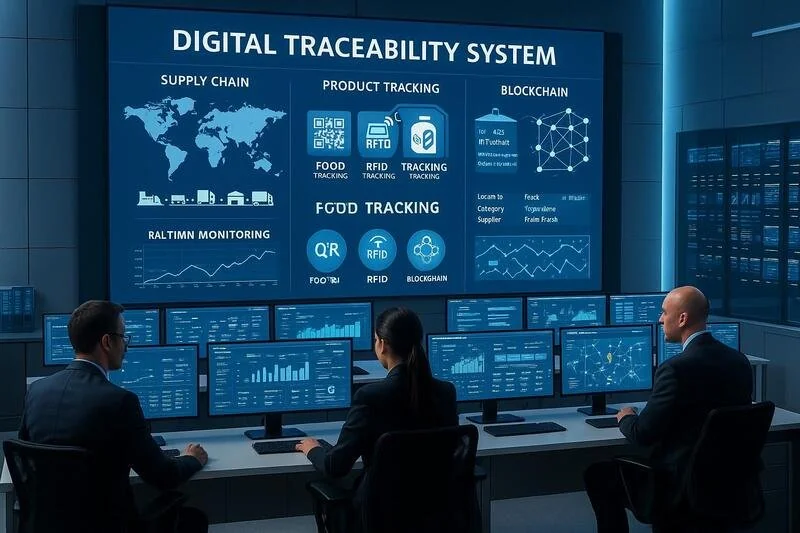

Sistemas de Trazabilidad

Tecnologías para el seguimiento y trazabilidad de productos a lo largo de toda la cadena de suministro, desde la materia prima hasta el consumidor final.

Aplicaciones: etiquetado con códigos QR, RFID, blockchain para trazabilidad, sistemas de gestión de lotes.

Beneficios de la Automatización en el Sector Alimentación

Mayor Seguridad Alimentaria

Reducción de la manipulación humana y control preciso de parámetros críticos, minimizando riesgos de contaminación y garantizando el cumplimiento de normativas.

Mejora de la Calidad

Mayor consistencia en los productos, detección temprana de defectos y control preciso de procesos, resultando en productos de mayor calidad.

Aumento de la Productividad

Incremento de la velocidad de producción, reducción de tiempos de inactividad y optimización de recursos, permitiendo producir más con menos.

Reducción de Desperdicios

Optimización de procesos para minimizar el desperdicio de materias primas, energía y otros recursos, contribuyendo a la sostenibilidad.

Trazabilidad Completa

Seguimiento detallado de productos a lo largo de toda la cadena de suministro, facilitando la gestión de incidencias y recalls si fueran necesarios.

Reducción de Costes

Disminución de costes operativos, de mano de obra y de gestión de calidad, mejorando la rentabilidad del negocio a medio y largo plazo.

Casos de Éxito en el Sector Alimentación

Automatización de línea de envasado en empresa láctea

Una importante empresa láctea implementó un sistema robotizado para el envasado y paletizado de sus productos, logrando:

- Aumento del 40% en la capacidad de producción

- Reducción del 25% en costes operativos

- Mejora del 15% en la consistencia de calidad

- ROI en menos de 18 meses

Sistema de inspección por visión artificial en procesadora de frutas

Una procesadora de frutas implementó un sistema de visión artificial para la detección de defectos y clasificación, obteniendo:

- Reducción del 90% en reclamaciones por defectos

- Aumento del 30% en la velocidad de clasificación

- Reducción del 20% en desperdicios

- Mejora significativa en la consistencia de calidad

¿Cómo Implementar la Automatización en tu Empresa?

Evaluación de Necesidades

Análisis detallado de tus procesos actuales, identificación de cuellos de botella y áreas de mejora, y definición de objetivos específicos para la automatización.

Selección de Tecnologías

Evaluación y selección de las soluciones de automatización más adecuadas para tus necesidades específicas, considerando factores como ROI, escalabilidad y cumplimiento normativo.

Diseño e Integración

Diseño detallado de la solución y planificación de la integración con tus sistemas existentes, asegurando la compatibilidad y minimizando interrupciones.

Implementación

Instalación, configuración y puesta en marcha de los sistemas de automatización, siguiendo un plan estructurado y con pruebas exhaustivas.

Formación

Capacitación del personal para operar, mantener y sacar el máximo provecho de los nuevos sistemas automatizados.

Monitorización y Mejora Continua

Seguimiento del rendimiento de los sistemas implementados e identificación de oportunidades de mejora para optimizar continuamente los procesos.